Excitement About Digital Printing

Excitement About Digital Printing

Blog Article

The Main Principles Of Digital Printing

Table of ContentsSome Known Facts About Digital Printing.Digital Printing - Truths3 Simple Techniques For Digital Printing

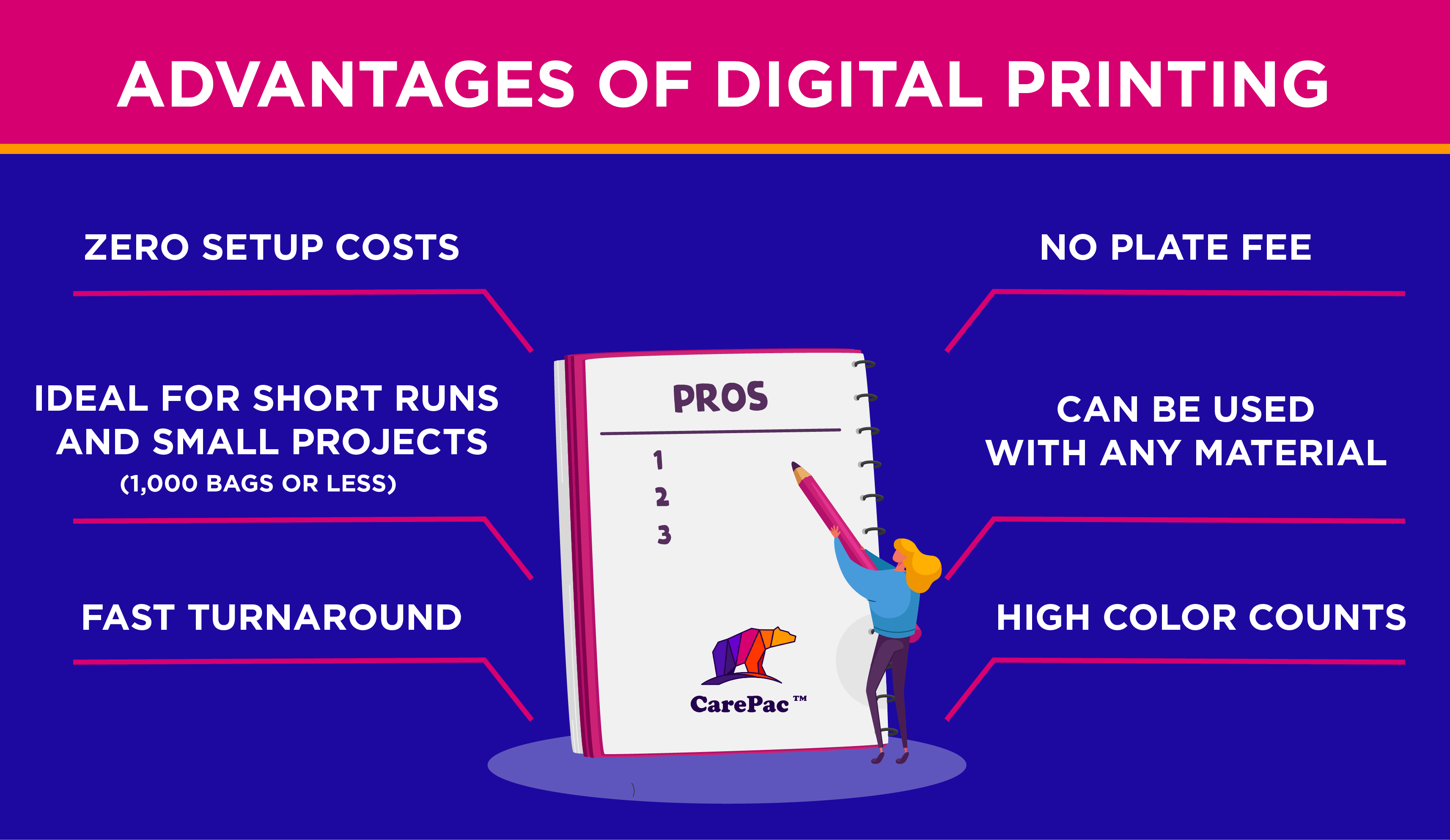

The liquid ink abides by the substratum via an electrostatic cost, ensuring dynamic colours and sharp detail. Digital printing likewise requires very little setup. Modern-day lithographic innovation has reduced setup times to around 15 minutes, electronic printing still leads to convenience with its near-instant readiness. In addition, electronic prints completely dry quickly, unlike lithographic prints, which need 2-3 hours to completely dry. This removes smudging risks and the need for drying racks. Below are the crucial methods which digital printing sustains greener techniques: One of the considerable environmental advantages of electronic printing is reducing waste. Conventional printing methods, like lithographic printing, commonly waste considerable quantities of paper and ink during the configuration stage. Digital printing gets rid of the demand for plates and other consumables, lowering waste throughout the production process. Several of the most typical applications consist of: Digital printing is ideal for producing calling card, flyers, posters and various other advertising products. It enables fast turn-around times and economical manufacturing, specifically for companies with smaller print runs. Digital printing is increasingly used in the packaging sector to develop one-of-a-kind, custom-designed product packaging.

Digital printing machine get rid of the demand for these plates, significantly lowering arrangement costs. Digital printing machine can integrate variable data into your prints, which enables very customized advertising products (Digital Printing). By personalizing your advertising products, you can boost involvement with prospective customers and improve the opportunities of transforming them right into real consumers

In digital printing, there are 2 various printing modern technologies to choose from: scan printing and single-pass printing. As a fairly new printing technology, Single-pass printing can not only boost publishing rate, but likewise increase publishing top quality, nevertheless, this calls for even more nozzles to be set up on the printing equipment. Service proprietors who have made use of digital inkjet printing machines recognize that textile digital printing is finished mostly by the printheads and printing inks.

Printers have to utilize more fluid inks to stop nozzle blocking and printhead failing. In order to prevent corrosion of the nozzle, the ink for electronic printing is much more expensive than the ink for conventional printing, and added ink filtration is required during the printing procedure. On top of that, the advantage of electronic inkjet printing is apparent just when using inks with a large color range. The electronic inkjet printing maker almost realizes the automated control procedure. In digital inkjet printing, the pattern is straight published on the material, getting rid of home plate making in rotary display printing. It not only conserves the important time of plate production, however additionally conserves the extra cost of plate making. At the very same time, even more and much more brands are now increasingly more approving of paying greater prices for faster distribution, such as providing a set of fabrics within a week or even 3 days, as opposed to weeks and months - Digital Printing. Yes, are a lot more expensive than traditional printing inks, but the digital printing procedure can save ink intake.

Today, the digital direct-injection printing machine has actually gone from proofing to the stage of medium-sized and large-sized production. The digital direct-injection machine has gone via the promotion period and went into the growth and maturity period. Both printing houses and brand name owners know the advancement capacity of electronic printing, and agree to raise investment in digital printing. The print top quality can in some cases also rival that of offset printing. Digital printing is more cost-efficient for brief print runs due to the fact that it requires less pre-press activities and less configuration than offset printing. If an error in balanced out printing is not caught prior to the plates are made, it will certainly be very expensive to make brand-new ones. While everybody regards really hopes that mistakes will be stayed clear of, it is sensible to plan for their here possible modification. On top of that, its accuracy is really high. This guarantees harmony in look across the board, lowering the probability that any item will need to be thrown away because of problems. Ensuring official statement the plates are in area, the ink secret is calibrated, and all the required changes have actually been made is a lengthy procedure when balanced out printing. Reduced pre-press steps suggest less time is required to set up journalism originally. This leads to a marked acceleration of turnaround time. When you require published products rapidly, this is an excellent alternative. Digital printing can be a lifesaver when you obtain an order in the nick of time.

has the advantage of just printing what you require. Balanced out printing's high setup expenses prevent it from being economical for runs of 100, 10, or even a solitary copy. A tailored message is constantly well received by customers. Digital printing enables easy personalization of promotional products. Smaller, more cost-effective sets allow firms customize each order. Have a sale for the go back to college. You can individualize your e-newsletters for repeat customers by resolving them by name. Variable information printing, such as direct-mail advertising with personalized codes and addresses, is ideally suited for electronic printing. Making modifications to your design at the last minute is much less complex with electronic printing. It aids in. And this printing approach assurances accuracy, so layouts will constantly look the very same. Alternatives for paper supply, finishes, and various other attributes will certainly remain to expand as technology developments. When it involves printing, Seattle Style and Print is amongst one of the most trustworthy companies around. Digital quick printing just requires 4 actions of style, review, printing and binding to get every little thing done. Typical printing covers a huge area and requires a big investment in innovation. The investment look at here of as much as 10s

of millions of yuan has actually made some tiny and medium financiers inhibited and powerless. The core of Digital Express is software. As long as the software application updates can maintain, Digital Express will certainly constantly go to the leading edge of the printing industry. And a collection of software application of a number of thousand yuan is too tiny compared to a set of devices of numerous

All about Digital Printing

is most likely that today's demands are various from yesterday.

Report this page